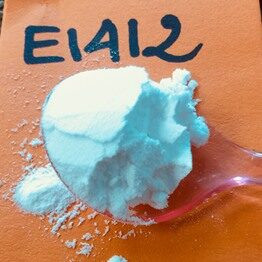

The Production Process of Canned Fish and Meat with Distarch Phosphate (E1412)

1. Selection and Preparation of Raw Materials

Start by selecting high-quality fish or meat. Clean and prepare the raw materials by removing any unwanted parts, such as bones

or skin, and cutting them into appropriate sizes.

2. Blanching

Blanch the fish or meat to kill bacteria and enzymes that could spoil the product. This process involves briefly boiling the raw

materials and then cooling them rapidly to preserve their texture and color.

3. Preparation of the Canning Liquid

Prepare a canning liquid or brine solution, incorporating Distarch Phosphate (E1412). This solution acts as a medium for the fish

or meat, enhancing its stability and texture during the canning process.

4. Filling the Cans

Place the blanched fish or meat into sterilized cans. Add the prepared canning liquid, ensuring that the product is fully submerged.

The liquid should cover the fish or meat completely to prevent oxidation and spoilage.

5. Sealing the Cans

Seal the cans hermetically to create an airtight environment. This step is crucial for preventing contamination and ensuring the

product remains sterile.

6. Thermal Processing

Subject the sealed cans to thermal processing, typically in a retort or pressure cooker. This process involves heating the cans to high temperatures to sterilize the contents and inactivate any remaining bacteria or enzymes. Distarch Phosphate (E1412) helps maintain

the texture and consistency of the product during this high-heat treatment.

7. Cooling and Storage

After thermal processing, cool the cans rapidly to prevent overcooking. Store the canned fish or meat in a cool, dry place to ensure

they remain stable and safe for consumption.