Derived from the cassava plant, is a natural ingredient that plays a crucial role in the textile industry due to its excellent adhesive and film-forming properties. As the industry increasingly prioritizes sustainable solutions, tapioca starch has emerged as a key component in enhancing both the quality and eco-friendliness of textile production.

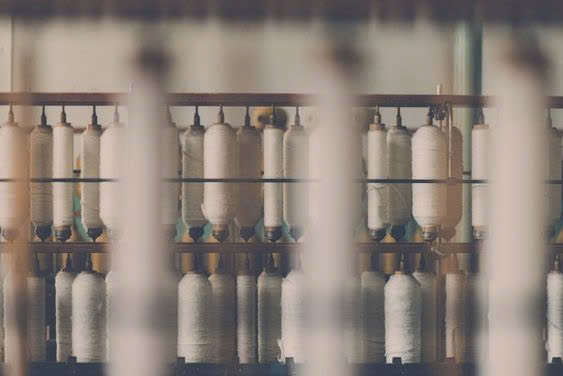

1. Strengthening Yarns in the Sizing Process

One of the primary uses of tapioca starch in textiles is in the sizing process. During this phase, tapioca starch is applied to yarns to strengthen them, reducing the likelihood of breakage during weaving. This not only improves the efficiency of the weaving process but also results in higher-quality fabric. The adhesive nature of tapioca starch ensures that the yarns are well-protected, leading to smoother, more consistent fabric.

2. Eco-Friendly and Biodegradable

In an industry where sustainability is becoming increasingly important, tapioca starch stands out for its natural and biodegradable characteristics. Unlike synthetic chemicals, tapioca starch is an environmentally friendly alternative that helps reduce the ecological footprint of textile manufacturing. Its use aligns with the growing demand for green solutions in the textile industry, making it a preferred choice for manufacturers committed to sustainable practices.

3. Enhancing Fabric Finish and Feel

Beyond its role in yarn strengthening, tapioca starch is also used in fabric finishing. It imparts a smooth texture to the fabric and adds weight, improving the drape and feel of the final product. This versatility allows manufacturers to produce textiles that not only meet high-quality standards but also provide a superior tactile experience for consumers.

4. Improving Overall Textile Quality

The application of tapioca starch contributes to the overall quality of textiles by ensuring that fabrics are strong, durable, and have a pleasing finish. Its ability to maintain the integrity of the fabric during both production and post-production stages makes it an invaluable resource in textile manufacturing.

Conclusion

Tapioca starch is more than just a functional ingredient in the textile industry; it is a vital component that enhances the quality, durability, and sustainability of textile products. As the industry continues to evolve towards more eco-friendly practices, the use of tapioca starch is likely to grow, offering a natural and effective solution for manufacturers aiming to optimize their production processes. By integrating tapioca starch into textile manufacturing, companies can achieve a balance between quality and sustainability, meeting the demands of both the market and the environment.