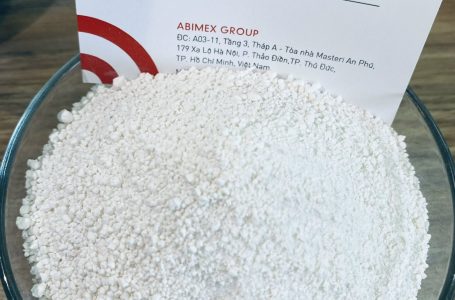

Tapioca starch, derived from the cassava root, is a versatile natural polymer widely used across various industries. One of its significant applications is in the textile industry, where it plays a crucial role in improving the quality and functionality of fabrics. This article delves into the importance of tapioca starch in textile applications, its benefits, and its impact on the manufacturing process.

What is Tapioca Starch?

Tapioca starch is a carbohydrate extracted from the roots of the cassava plant (Manihot esculenta). Known for its excellent thickening and gelling properties, it is a popular choice in the food industry. However, its utility extends beyond food, making significant contributions to the textile sector due to its biodegradable and non-toxic nature.

Applications in Textile Industry

1. Sizing Agent: One of the primary uses of tapioca starch in textiles is as a sizing agent. During the weaving process, yarns need to be strong and resistant to abrasion. Tapioca starch is applied to warp yarns to enhance their strength, reduce breakage, and improve their performance during weaving. This process, known as sizing, coats the yarns, creating a protective film that reduces friction and wear on the fibers.

2. Finishing Agent: Tapioca starch is also used in the finishing process of textiles. It imparts a smooth, polished appearance to fabrics, making them look more appealing. The starch fills in the tiny gaps between fibers, creating a smoother surface that reflects light better, thus enhancing the fabric’s luster.

3. Printing Thickeners: In textile printing, tapioca starch serves as a thickener for dye pastes. Its excellent viscosity and film-forming properties ensure that the dyes are uniformly applied to the fabric, resulting in sharp and vibrant prints. This application is particularly valuable in screen printing, where precision and consistency are crucial.

Benefits of Using Tapioca Starch

1. Biodegradability: One of the significant advantages of tapioca starch is its biodegradability. Unlike synthetic sizing agents, tapioca starch breaks down naturally, reducing environmental pollution. This attribute aligns with the growing trend towards sustainable and eco-friendly textile production.

2. Cost-Effectiveness: Tapioca starch is relatively inexpensive compared to other natural and synthetic sizing agents. Its abundance and low cost make it an economically viable option for textile manufacturers looking to reduce production costs without compromising quality.

3. Non-Toxicity: Being a natural product, tapioca starch is non-toxic and safe for workers handling it and for consumers wearing the finished textiles. This safety aspect is crucial in maintaining healthy working conditions and producing hypoallergenic fabrics.

Impact on Textile Manufacturing

The use of tapioca starch in textile manufacturing has a significant impact on both the quality of the finished product and the efficiency of the production process. By enhancing yarn strength and reducing breakage rates, it minimizes downtime and maintenance costs in weaving operations. Furthermore, its role in fabric finishing and printing ensures high-quality, aesthetically pleasing textiles that meet consumer expectations.

Sustainability and Future Prospects

As the textile industry moves towards more sustainable practices, the role of natural products like tapioca starch becomes increasingly important. Its biodegradable nature helps reduce the environmental footprint of textile manufacturing. Additionally, ongoing research into improving the functionality of tapioca starch could lead to even more innovative applications, further cementing its place in the industry.

Conclusion

Tapioca starch is an invaluable asset in the textile industry, offering a range of benefits from enhancing yarn strength to providing a polished finish on fabrics. Its cost-effectiveness, non-toxicity, and biodegradability make it an ideal choice for manufacturers aiming for high-quality, sustainable production. As the industry evolves, the role of natural products like tapioca starch will likely expand, driving innovation and sustainability in textile manufacturing.

By integrating tapioca starch into various stages of textile production, manufacturers can achieve superior quality and performance, aligning with both economic and environmental goals. This versatile natural polymer is poised to play a critical role in the future of textiles, promoting a greener and more efficient industry.